A.M.P Automation has considerable experience in the handling & packing of Crisps & Snack foods, whether they are pre-packed in bags, or even naked.

Our innovative Robotic Pick & Place systems are ideally suited to handling such products; reducing manual handling & labour costs and providing complete automation of processing & packaging lines.

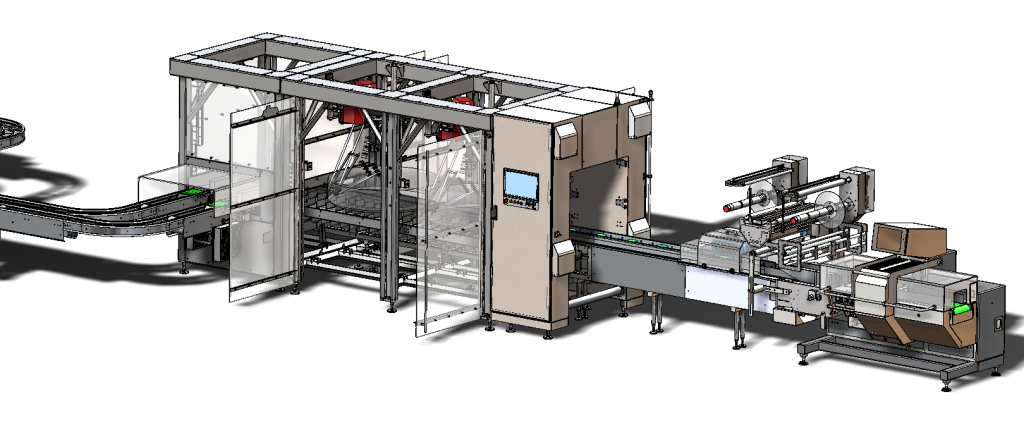

Our lines can be directly coupled to VFFS bag-makers, providing a compact and efficient packaging line. Alternatively the IPAX system can form part of a WIP process, where bags are delivered in bulk to one or more A.M.P Automation bag sorters/feeders, before being sorted and packed by the Robotic Pick & Place system.

Naked products such as Extruded Sticks can also be fed directly from the production line, or where necessary sorted with our bespoke Feeding Systems to ensure that products are correctly presented to the Pick & Place robots. Feeding Systems.

MULTI-PACKS MADE WITH A.M.P AUTOMATION ROBOT LINES CAN SAVE MORE THAN 30% IN PACKAGING FILM WHEN COMPARED TO A VERTICAL PACKGING SOLUTION!

Typically, the IPAX system will load snack bags directly into a flow-wrapper infeed, either placed flat on top of each other or even loaded ‘on edge’ as a special presentation.

Snack bags are usually multi-packed in 5’s and 6’s, but we have the capability of loading as many as 32 bags in a multipack.

The IPAX Snack Pick & Place system can also be used to load cardboard cartons/cases as an environmentally friendly pack presentation.

We also provide an extremely compact solution for the multi-packing of single-flavour bags, which uses our Patented system incorporating cutting-edge Linear Track technology. MMP Packing

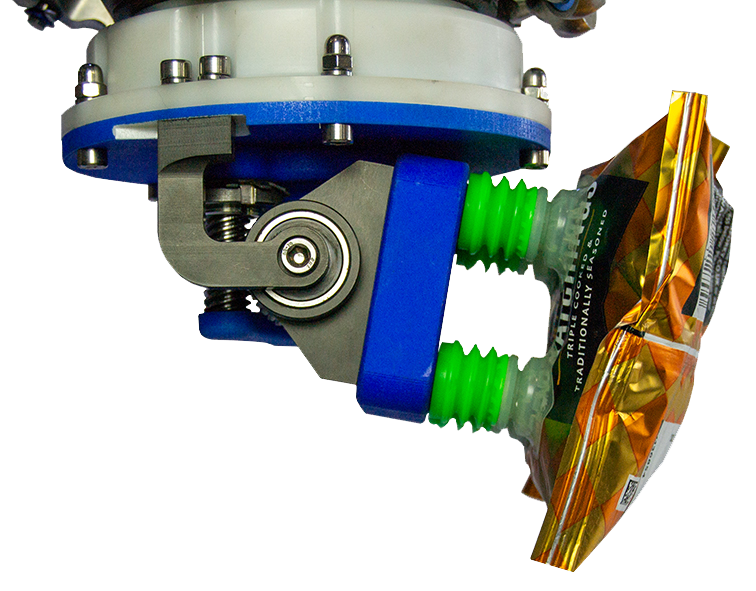

Our end of arm tooling is designed & manufactured in house, ensuring that your products are handled delicately whilst providing optimum performance. Mechanical and vacuum based picking heads are used to best suit the specific characteristics of your product.

A.M.P Automation systems integrate with upstream & downstream equipment such as tray de-nesters, labellers, check weighers, metal detectors etc. If your baskets, trays or cases need subsequent Palletising, we can help with that too. – Please see our Robotic Palletisers page.

Highly skilled engineers perform the installation and commissioning of the equipment, ensuring that the lines work as expected and that your staff are suitable trained to operate and maintain the equipment.

Our after-sales department provides a complete range of services that ensures that the machinery will perform reliably throughout its entire lifecycle.

Are you ready to discuss your next automation project? If so please contact us to arrange a free consultation.

© 2024 A.M.Packaging Ltd. T/A A.M.P Automation | All Rights Reserved |

Registered in England. 1525421 | VAT No. GB 351 8795 24 | Built By: drumBEAT Marketing