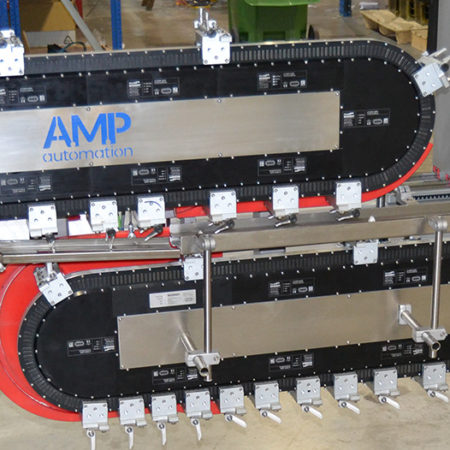

The linear transport system we use is a Beckhoff XTS (eXtended Transport System) which brings together the benefits of rotary and linear systems. XTS is a mechatronic system containing all functions necessary for operation: a modular, fully integrated linear motor with power electronics and position measurement in a single device, a mover as a moved part and a mechanical guide rail.

XTS allows individual product transport with a continuous flow of material. Due to the low construction volume, the energy efficiency and the size of a machine can be significantly reduced compared to conventional systems.

XTS adapts itself precisely to the customer requirements: the arbitrary number of movers, the modular path guidance, and the controllability of each individual mover allows precise configuration to suit the product.

The mover is made of a light and solid aluminium alloy. Thanks to their arrangement the rollers allow backlash-free travel on the straights and in the curves. The rollers cause very little running noise and are particularly low-wear without lubrication of the guide rail. The attractive forces of the magnetic plates are largely balanced by the opposed arrangement so that the rollers and the rail do not have to absorb the comparatively high attractive forces of the magnets.

Up to 4m/s can be achieved with the feed system, without any jerking and still with maximum positioning accuracy. Synchronisation, stopping and starting can be accomplished at any of the stations on the entire path. Added to this is a sensitive response; jerk-free acceleration profiles even allow the transport of open liquids.

There are no sliding contacts or cables to the moving part, it is a purely passive mover, this results in maintenance and spares being kept to a minimum. The friction is also very minimal, which means there is no development of heat in or on the mover, and with the mover weighing less than 350g it is less susceptible to wear and damage.