AMP Automation has a long history of supplying multipack equipment, from single flavour to variety packs. Initially supplying flow wrapping machines we now specialise in the design and build of complete automated turn-key projects for pick and place machines.

With innovative design and smart solution’s we design systems that meet the demands of the customers’. We have several patented and patent-pending designs that have revolutionised the way lines are built. Some designs include an IPax line that can multipack on-edge and on-flat, without increasing the size of the line or adding any complexity to it.

Our pick and place machines can include integration of feeders, delta robots, flowrappers and other ancillary equipment. The systems can be all new machinery or integration with some of the customer’s current machinery. As well as the physical integration we also integrate the software with the customer’s existing equipment. Our software team are trained to install and program different brands of control systems.

Preference of control systems are determined on the suitability to the project, and/or if the customer has a preferred supplier.

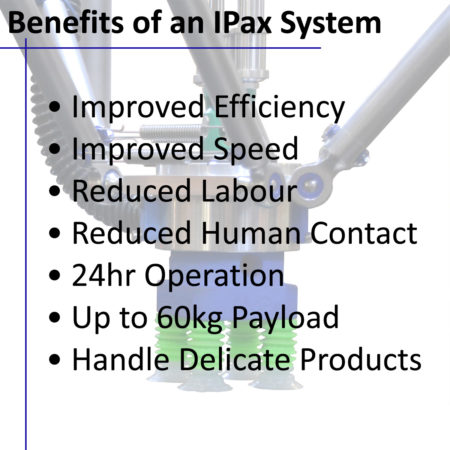

Pick and place machinery is used in a variety of ways whether it is picking multiple items with pay loads up to 60kg, or picking light delicate bakery goods with the use of soft picking hands.

Naked or wrapped goods can be picked with our systems, each picker hand is designed around the product for optimum performance.

Easy to use HMI screens allows for quick changes to be made to the IPax robot if a different product, or format, is to be used on the line. Communication upstream and downstream also helps to adjust the parameters from a single point HMI screen.